Weaving Project 28: a new loom

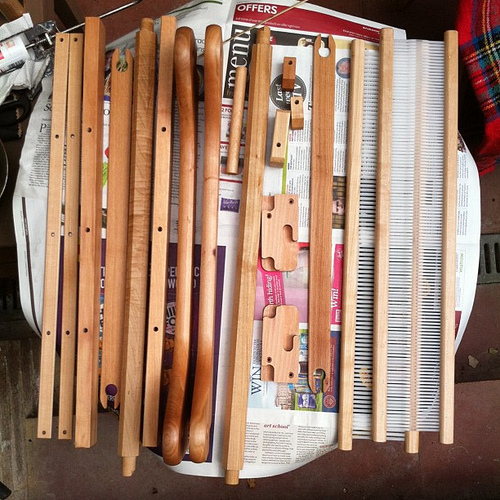

For my birthday I received an Ashford Rigid Heddle 24” loom. It came with a 7.5dpi reed, and I also got a 10dpi reed. For those who don’t know, Ashford Rigid Heddle looms arrive untreated and unassembled. So, the first job was to buy some oil and after consulting a couple of web pages, and comparing the advice with what my local Robert Dyas had in stock, I settled on some Danish oil. The oil recommended 3 coats on untreated wood. So 3 coats I duly applied.

(Apologies for the varied quality of the photos below, a lot were snapped on my phone camera as I worked, and I only decided after the event that I wanted to have this post as something to look back on in the hope that I can see how my weaving skills have progressed)

Having let the final coat of oil dry, it was assembly time. This was a bit nerve racking actually. I enlisted Richard’s help to hold things, and double check the instructions in places of confusion (and there were a couple, especially relating to attaching the pawls) and after an hour or so we’d got it assembled. At this point I realised that it was much bigger than I’d expected.

Next up was warping the loom. I was following the project in the “Learn to weave on the Rigid Heddle” booklet that came with the loom, so making a scarf. I bought wool to match the hat I made last year (Rowan Pure Wool DK in anthracite (for the warp) and shale (for the weft)). This is not cheap wool and I’m still in two minds whether this made me feel more pressure as I got started. It is, however, good wool that I’ve worked with before, albeit in a different craft. I followed the dimension instructions in the booklet using the 7.5dpi reed and 84 warp ends. Warping took an hour and a half I guess. And made my back hurt. But, seemed successful.

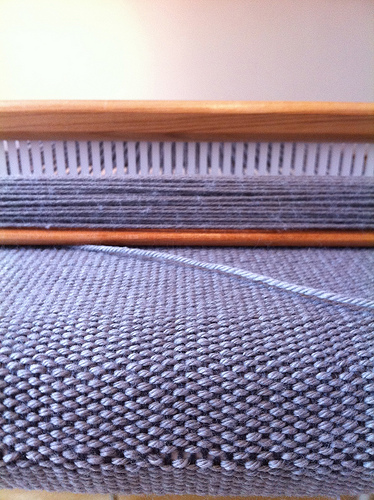

And then the weaving. I think I’d set myself up for a fall. I was nervously excited to get going, and quite soon disappointed with how uneven my tension was. I think I’d got myself to a reasonable level of competence on the little picture frame loom, and the work I did with the bookmarks in the run up to Christmas was the best I’d done. Using a new tool is different. And this is the first loom I’ve had with a heddle, or a winding mechanism. Lots of new things to get used to and it’s been a struggle to maintain a consistent weave (visible in the shot below).

As I have done for a while now I finished it off with hemstitching - I followed this tutorial just to ensure there wasn’t anything different between finishing at the smaller scale I’ve been used to.

After cutting it off from the loom, and taking a couple of snapshots, I pushed it straight into the washing machine for a 30 degree wool wash. It was then laid on a blanket on a blocking board and blocked to be 10.25” wide all the way along it. It is a bit shorter than I’d have liked, coming in at just under 55”, but it is a wearable length.

Lots of things learnt, or at least observed in preparation for learning:

- starting is important — my starting bit was a lot less tightly packed than the rest, this made it a bit tricky and means that one end of the scarf is a bit looser and less satisfying than the other

- focus on the selvedges — keep them in mind at all time — it’s hard to rescue sloppy/uneven edges

- wind the fabric on frequently — it appears that the tension I apply when beating the fabric differs according to where on the loom the fabric is — if it’s a long way from the heddle, the tension is loose, if its close to the heddle, the tension is tight. I need to work on this. A lot.

- in a relaxed, not under tension, state, it will (probably) look better so don’t abandon all hope

- washing and blocking will help, but won’t miraculously fix the edges. Refer to the 2nd point above :-)

In retrospect, I should have followed the advice in the weaver’s idea book and started with a sampler (which is what my next project will be) so I got used to the loom and the yarn on something designed to be disposable/a learning project, but I thought that I should follow the guidance of the loom manufacturer. Also, I like making things that are usable.

Overall, I’m somewhat pleased with it — but far from delighted — the edges aren’t straight enough and the weave not even enough to delight me. The best description of my feelings is probably that I’m relieved to have made something that I can and will wear — there were times whilst I was making it that I didn’t think this would be the outcome — and whilst it has been a lovely warm weekend I have sat with it wrapped around my neck and am very pleased to discover that it isn’t in the slightest bit itchy. It is rather more rustic than I was hoping for but it hasn’t discouraged me from moving on to the next project — and compared to my first ever weaving project it’s positively amazing.